The modern ski industry is full of brands attempting to diversify offerings to squeak out marginal new revenue streams: hard goods companies producing apparel, technical apparel brands doubling down on streetwear, not to mention bizarre collaborations, limited releases, and other marketing gimmicks. In an era of quantity over quality, there’s something profoundly reassuring about a brand focused on creating one thing and one thing well — and nobody has done that with climbing skins as long as Pomoca.

The name of the brand, officially founded in Switzerland in 1933, tells the story:

PO: from the French “peau,” meaning skin

MO: from mohair

CA: from the French “caoutchouc,” meaning rubber

The brand’s storied history began with hotelier Louis Dufour and his son, Éric. Louis pioneered winter sports in the French-speaking part of Switzerland, both as co-founder of the Swiss Ice Hockey Association and as the first importer of skis. As there was no lift infrastructure then, climbing skins were the only way to get to the best snow, so Louis created a brand to develop them. The family business produced the first non-slip mohair skins in 1939, the first adhesive skins in 1970, and a proprietary attachment system by 1980. Though the brand sold to the Oberalp family (Dynafit, Salewa, Wild Country, Evolv, LaMunt, Pomoca) in 2011, production remains in Switzerland, and the focus is the same: “Still making skins, only skins.”

Arthur Guinand, Pomoca’s marketing director.

Guinand explains that by focusing on one offering, the brand can maintain unparalleled attention to product quality and customer service.

Arthur Guinand

“If you start touring, most people don’t know the skin brands,” continues Guinand. “But as soon as the skins are failing, they remember the skin brands and say, ‘Okay, I will never go and buy this brand again.’ Our rubber is special as you don’t have any exchange of water from the hard side to the glue side. And this is one part of the success of Pomoca: it’s definitely the stability of the glue.”

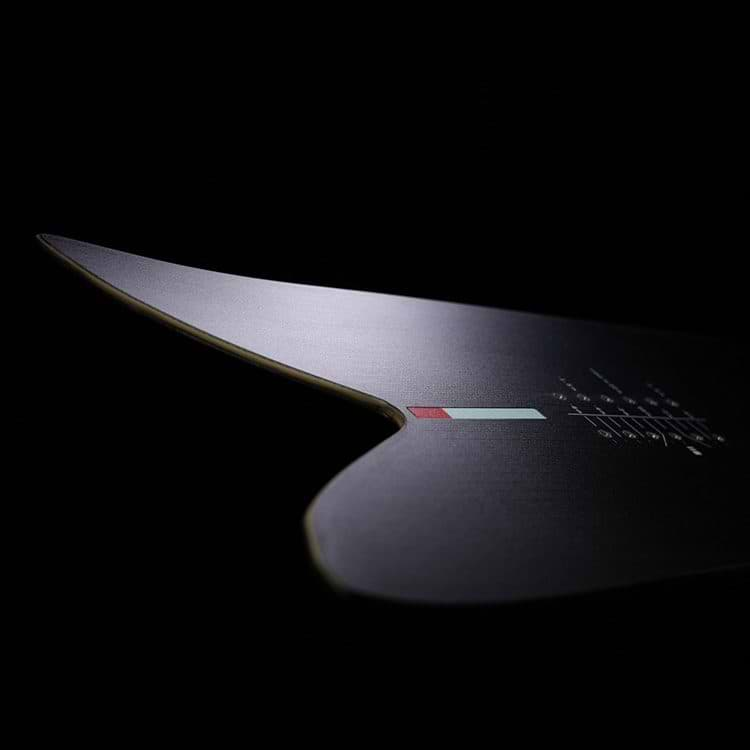

Pomoca’s proprietary rubber membrane allows the brand to apply less than half the glue of its competitors, enabling the skins to stick together without using a liner. Liners (or “skin savers,” as they’re colloquially labelled among other brands) are designed to make it easier to unstick skins from each other. Pomoca’s skins are designed to fold and stick together, glue surface to glue surface and pull apart easily without damaging the glue. Liners, meanwhile, can carry plastic solvents that enter the glue and decrease its efficacy.

As one American sales representative told Arthur, “You can change everything on Pomoca skins, but never change the glue.”

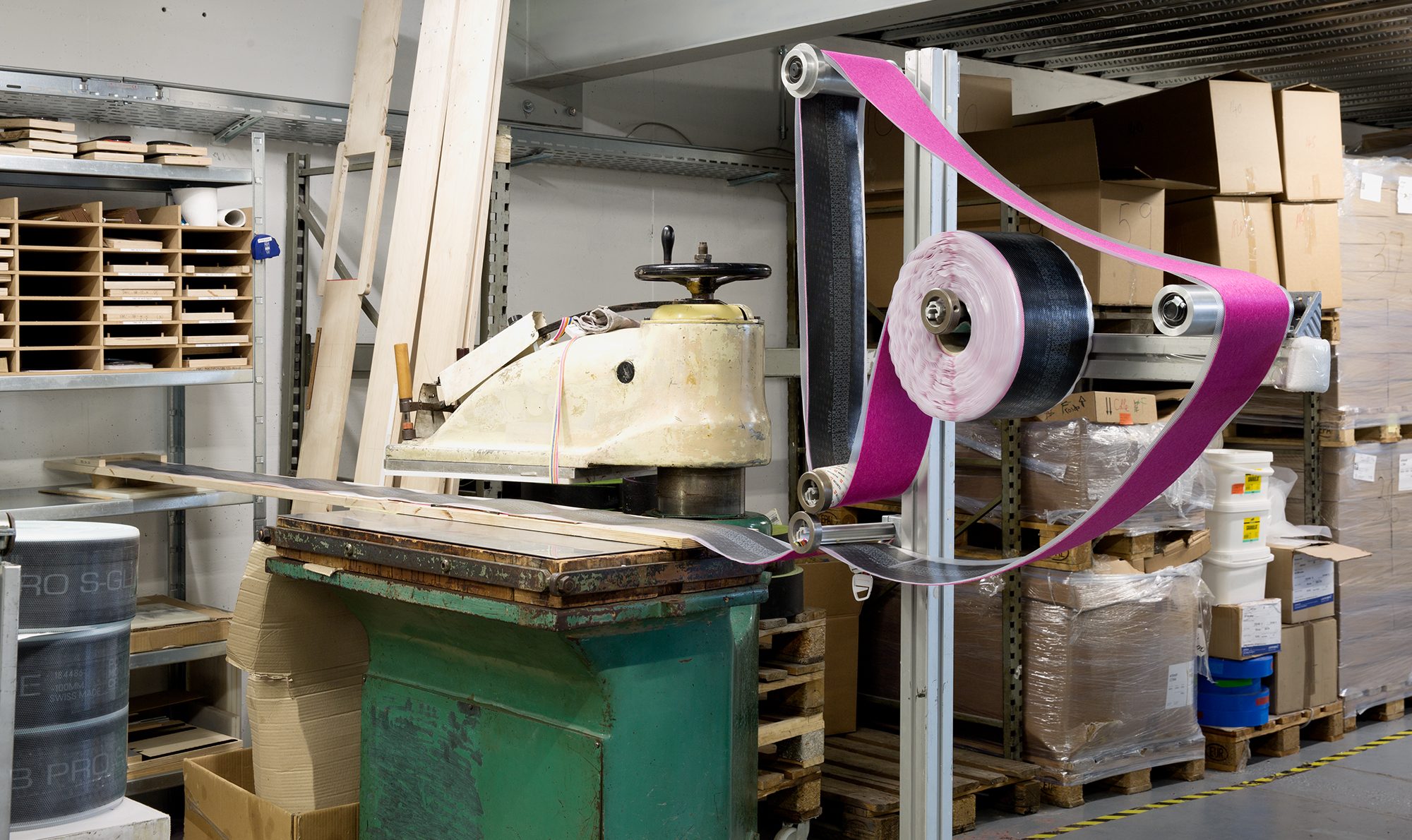

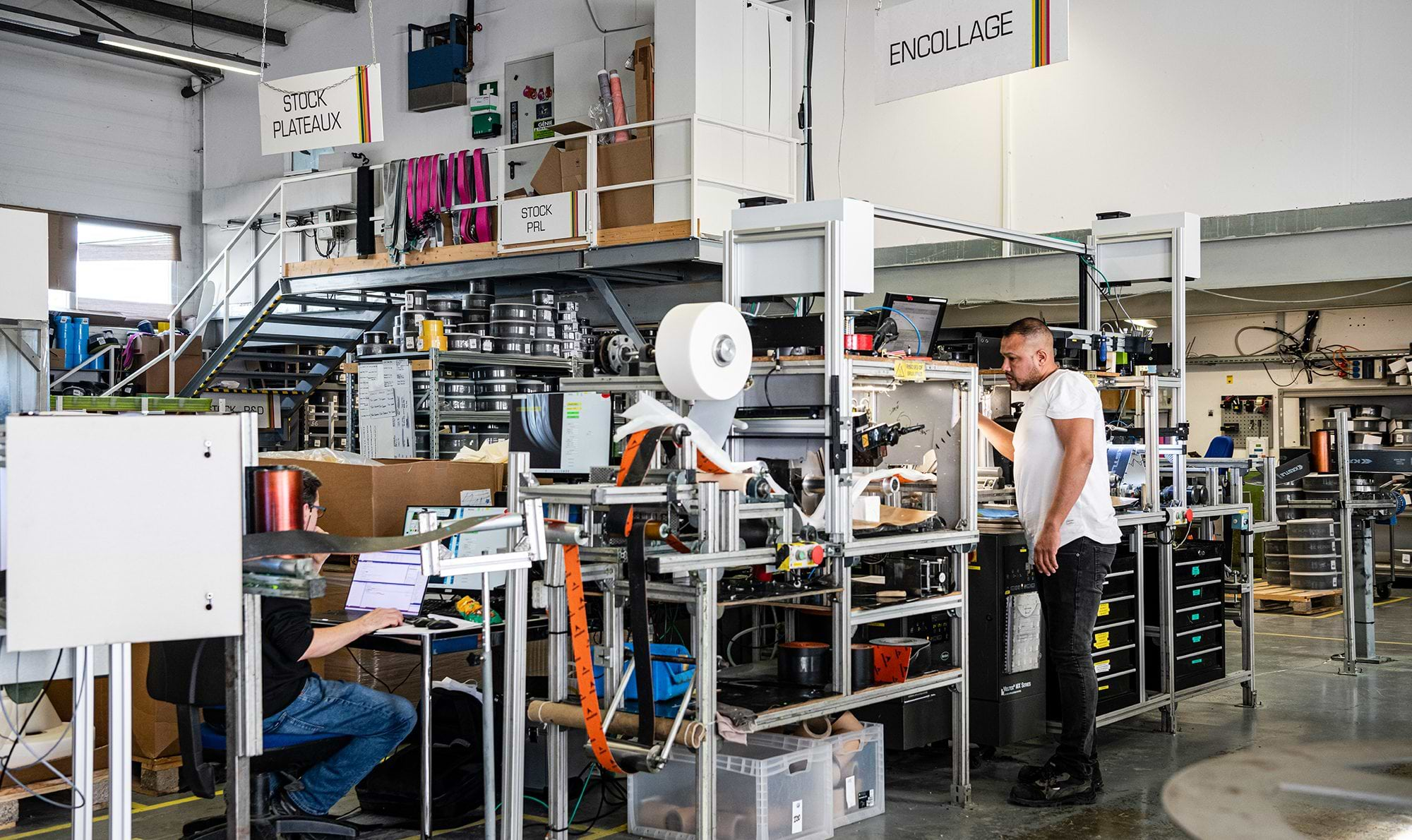

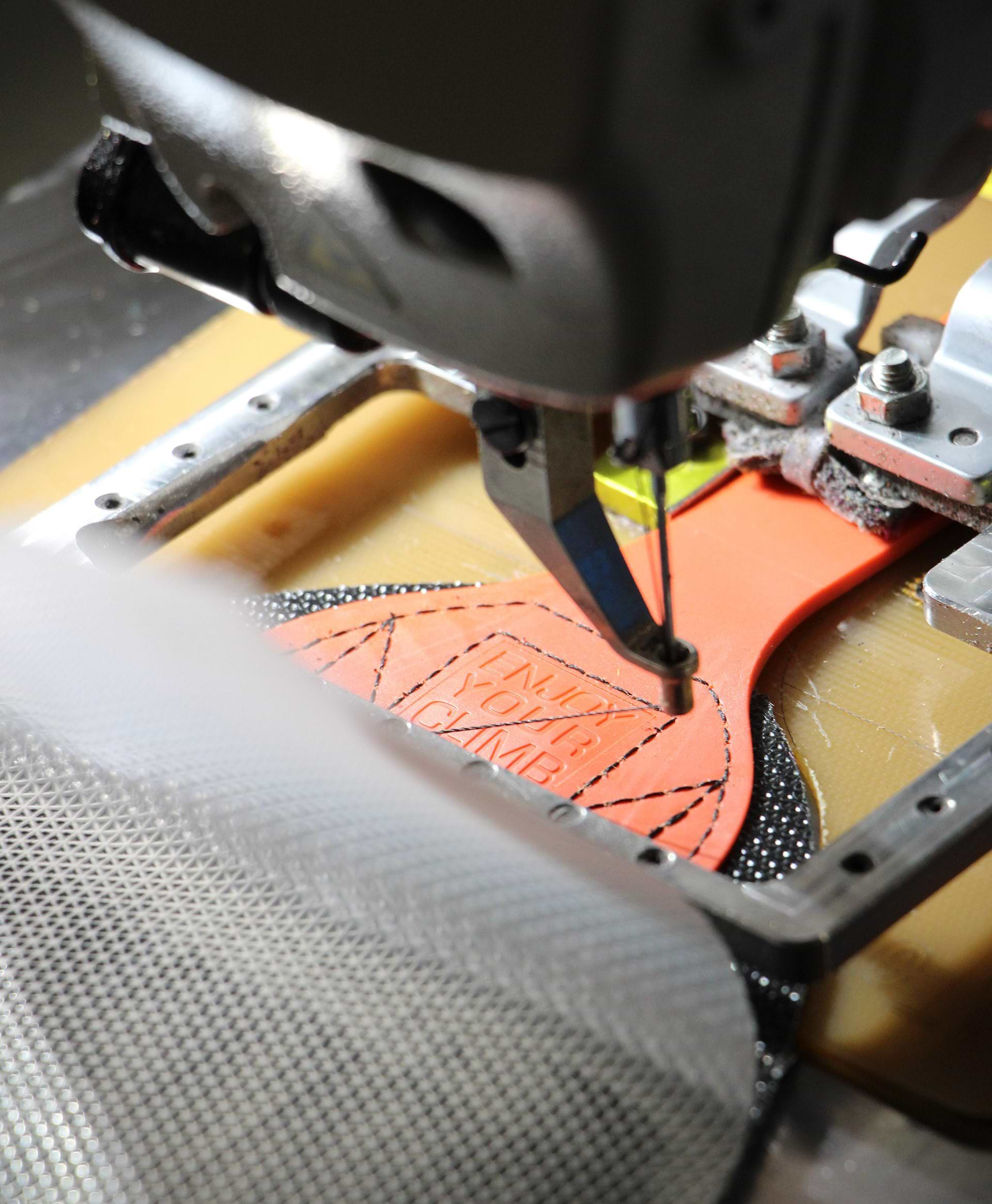

Oberalp is currently building a new state-of-the-art factory for Pomoca to house its production facility. The facility will be fully powered by renewable resources (primarily rooftop solar and hydroelectric energy). All of the company’s machinery is custom-configured for its unique manufacturing process. More importantly, every step of the production process—from weaving and cutting to gluing and colouring—is hand-coordinated by a human technician. After the gluing process, the skins undergo another five steps of human quality control and inspection.

Pomocą recognizes that an environmentally conscious manufacturing facility is only as sustainable as its product. “We always try to have a long-lasting product,” says Guinand. But we [also] advise our customers to repair the product. We built a system of service centres where you can repair the skins. We conform different shops to Pomoca standards to re-glue skins, repair top fix, back fix, stitching, and if you rip the skins, all to have a long-lasting product.”

Behind this success is a small but diverse team of 30-40 employees. A former skimo World Cup winner served as an intern. Another factory worker from Cameroon had never seen snow before arriving in Switzerland. While Pomoca values a wide range of perspectives, abilities, and backgrounds, it also seeks to increase employee understanding of the product and foster a familial environment through a concerted effort to teach all employees how to ski tour. Given that everyone always has an excellent grip and glides on the skin track, Pomoca’s efforts are likely very successful.