In 2023, the boutique, rider-owned Revel Bikes brand shocked the bike industry by unveiling the world’s first 3D-printed full-suspension mountain bike. Concept releases are expected in the lucrative automotive industry but have never been a “thing” in the more secretive and tight-lipped mountain bike industry. So, it turned heads when a small, relatively new bike company released a concept bike.

If there’s one word to describe Revel Bikes, it would be innovation. Their headquarters in the riding Mecca of Carbondale, Colorado, could be one of the nerdiest centers in the bike world. Debates about suspension kinematics, composite materials, and obscure terms like anti-squat, anti-rise, and leverage ratios are standard lunchroom (or lunch ride) topics. The passion here is palpable, and the team is just as excited about the obscure design features and tiny tweaks as they are about shredding these cutting-edge bikes on the trail.

Launched in 2019, Revel made a name through thoughtfully engineered bikes based around their proprietary suspension platform — CBF or Canfield Balance Formula. The kinematics and leverage charts are enough to make anyone cross-eyed. Still, the theory behind CBF is to center the moving parts around the chainring (the center of curvature). In effect, this segregates the drivetrain from the suspension resulting in zero loss of pedaling power throughout the entire range of travel, no matter if the suspension is compressed or braking power is applied. The result is a bike that feels like a monster truck climbing up chunky terrain with unlimited traction on the rear wheel, and when screaming downhill, it gives you the confidence to grab a handful of brakes without getting pitched.

CBF stands head and shoulders above other suspension platforms regarding pedaling proficiency, so it’s no surprise that the design team is focused on cross-country and enduro bikes. However, the genius behind CBF—Chris Canfield—is a former World Cup downhill racer who originally designed the suspension for longer travel bikes in 2015. Since then, he’s been bugging Revel founder Adam Miller* for a downhill bike. The new 3D-printed concept bike was the perfect excuse to enter the DH world finally.

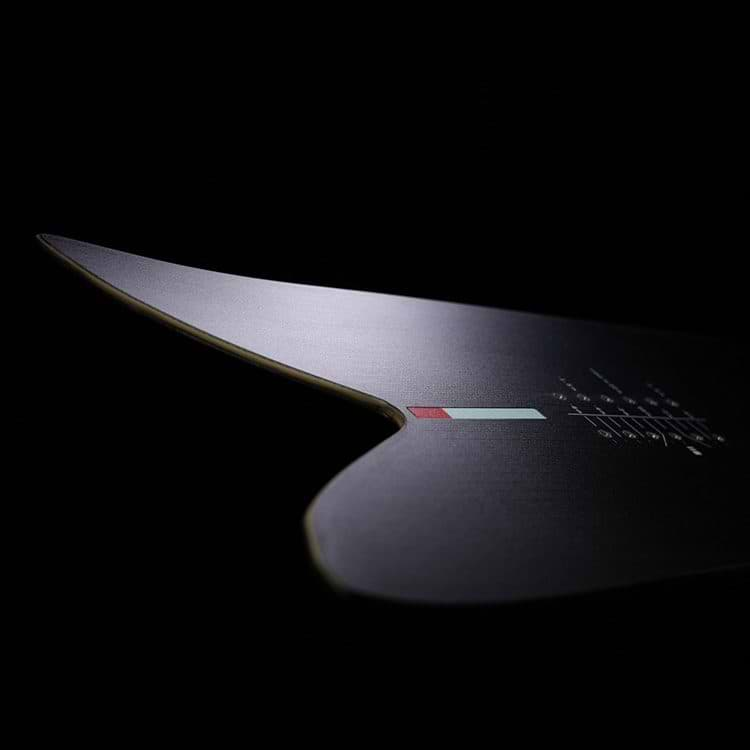

Enter the Rodeo — a burly 200mm downhill beast 3D printed in Silicon Valley by Arevo using a carbon composite material called thermoplastics. Famous in the aerospace and aeronautics manufacturing world for their high strength-to-weight ratio, thermoplastics are just beginning to enter the cycling sphere. All-carbon bikes are composites consisting of carbon fibre and epoxy. The thermoplastic used in the Rodeo comprises carbon fibre strands and a nylon-based material as a binder instead of epoxy. The benefits are that thermoplastics can be run through a robotic 3D printer head, they’re stronger with better impact resistance than traditional lay-ups, they don’t use unhealthy volatile epoxies, and the final composite material is fully recyclable.

The Rodeo is purposefully engineered to take on Red Bull Rampage — the gnarliest of all mountain bike competitions. Miller thought, “To prove this type of manufacturing, this concept, let’s make a bike that people are going to do crazy stuff on. And if we can do that, we know we can apply this technology to other products.” The Rodeo has proven that a 3D-printed bike is entirely possible, but currently, the main drawback is cost.

Now, it’s the engineering and programming time that jacks the cost up, not the material itself. It’s still technical work to fine-tune how the robotic printer head puts out the carbon strands, where the fibres go to be most effective and to strengthen the overall design. With time and production at scale, 3D-printed bikes could be the exact cost or even cheaper than current manufacturing processes, and the future possibilities are exciting. Theoretically, a customer could message the Revel design team and request a slight change in reach, frame length, or increased suspension. With a few simple tweaks of the computer model, a complete custom bike could be printed at manufacturing costs like a factory model. But for now, the Rodeo would cost more than a Rivian, leaving downhill riders drooling in anticipation.

Revel is not new to thermoplastics. They’ve been producing Fusion Fibre rims for more than four years now. Fusion fibre is a polymer composite that is stronger, lighter, and has a dampening effect, creating a quieter and smoother ride than traditional carbon or aluminum rims. Manufactured in an aerospace facility, the process is entirely robotic, leaving no room for inconsistencies and requiring less energy and material. The bonus is that the material is fully recyclable.

While it’s a curious juxtaposition – striving to be an engineering powerhouse set to the pace of a small family-run brand – it seems to be working for Revel. Clearly, the company is set on a fully mechanized future, but Revel’s heart remains the 28 fine folks (and 16 dogs) in Carbondale, on the forested slopes of the Rocky Mountains and six people in Taiwan. Company culture and work-life (ride) balance are critical to making every employee feel like family and engaged in the community. Whether supporting seasonal racing ambitions, lunch rides on Red Hill, or BBQs at the shop before the community fair, the rider-owned and passion-driven company aims to make the best bikes in the world and have fun doing it.

* Adam Miller has recently left Revel to pursue new projects.